Status of Fridge Valves

As of 2022-12-22.

- The run valve is always closed.

- The bypass valve is always controlled remotely (i.e. Cryo Control Panel).

- Do not manually turn the run and bypass valves. It will mess up the valve positions in the remote control.

- In case of trouble, you should fully close the bypass valve remotely or manually. To do that manually, the motor power has to be disabled on VI, or remove the motor from the valve shaft. A black Allen wrench is taped on the motor support.

Fridge Modes

- Standby mode

- We need to determine the setting for fridge valves and gate-valve bypass that allows us to keep things cold but uses the least amount of liquid helium as possible.

- The place to start for this study is to overfill the nose to the top of the heat exchanger, crack the run valve, and open the gate-valve bypass just a little so you get something like ~1 slm going through the separator flow.

- The pressure in the nose will build a bit which is what you want. You want to let it rise to maybe a few hundred Torr and find out what the optimal storage temp/flow is.

- This is the mode we should keep the system in when we are not doing something with the fridge.

- It's also possible to let the helium in the nose boil off and just keep the separator cold. This would be the recommended state if we do not use the fridge for many days. However, every time we let the nose empty we will have to cool it down again which is inefficient both in terms of time and helium.

- TE mode

- There is a range of different temperatures we might want to perform TE measurements at. We need to learn what run valve and gate-valve bypass setting correspond to what temperature of interest.

- We need the backing pump running with the gate-valve bypass cracked with the nose being filled by the run valve but at the least amount open to hold the temperature in the nose fixed. We want to be able to do this for various temperatures (1.7K, 2K, 2.5, 3K...).

- 1.7 K ↔ 8.461 Torr — https://qdusa.com/support/helium_vapor_pressure.html

- 2.0 K ↔ 23.48 Torr

- 2.5 K ↔ 76.73 Torr

- 3.0 K ↔ 180.4 Torr

- The run valve setting should be fixed so that it's not introducing helium at a different temperature than the nose reservoir at a fluctuating rate.

- The best temperature sensor we have at the moment is the 100 Torr red brick Baratron. Use that helium vapor pressure to determine the temperature of the nose.

- This could be uniquely challenging because of the way the nose fills (no fill tube just sprays). The time required for the target to thermalize is longer for lower temperatures. You would need to wait at least 3 times the t1 (longitudinal relaxation rate).

- As a starting point, we should demonstrate that we can hold a fixed temperature in the nose for at least 30 minutes at these various temperatures.

- Operations mode

- Operations means that the microwave is running and the beam will be coming once every minute for 4.4s. This is an additional heat load to the system. Here we want our maximum cooling power and lowest temperature possible.

- All roots are running and the run valve is open so we are seeing about 20 slm on the Main Flow. The run valve operating on a PID on Main Flow may be helpful here.

- We should demonstrate the feasibility of this mode over a long period of time.

Fridge Related Procedures

1. Fridge Fill Procedure

Old Procedure for Filling the Fridge with LHe (Until November 2023)

Procedure for Filling the Fridge with LHe to Start the "Standby" Mode

It is to prepare for the shielding block installation conducted in the week of 2022-12-19 (Mo).

- Stop the automated control.

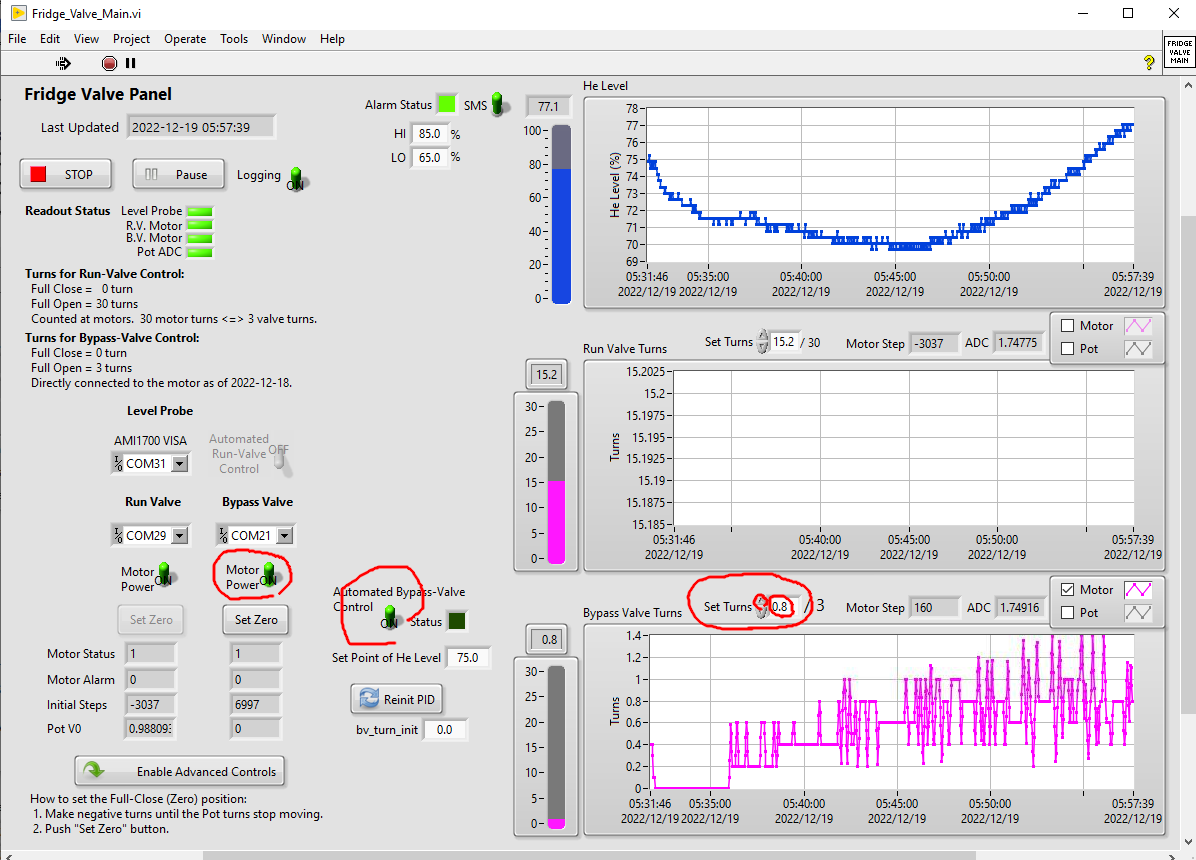

- Sit in front of the target computer and open "Fridge_Valve_Main.vi" (if not opened) by pressing the "Open" button at the right side of Cryo Control Panel.

- Confirm that the automated control of the bypass valve is running. If not, this procedure might not be applicable.

- Disable the automated control, by clicking the toggle switch labelled "Automated Bypass-Valve Control".

- Fill the fridge with LHe.

- Disable the SMS (Discord) alarm, by clicking the toggle switch labelled "SMS".

- Set the turn of the bypass valve to "1.0", by entering the value to the "Set Turns" box (or clicking the up arrow of the box multiple times).

- Confirm that the Main Return flow increases on the right-side strip chart in this page; https://e906-gat1.fnal.gov/data-summary/e1039/target-par-preset/return_flow.php

- Increase the turn step-by-step (wait for 20 seconds per +0.1 turns), until the Main Return flow reaches about 50-80 SLM. Usually the turn should be 1.4-1.8.

- Wait until the nose LHe level becomes 100%.

- If the change is too slow, you can increase the flow upto 100 SLM, with closer attention.

- Start watching the fridge temperatures on the left-side strip chart opened above.

- Wait until the "Heat-Ex Top" temperature goes above 1,400 Ohm. Be prepared to make the next step immediately, since the change is sudden

- Set the turn to "0", by entering "0" to the "Set Turns" box.

- Confirm that the Main Return flow becomes ~5 SLM or less.

- Pause the fill.

- Open "THCD_401_Main.vi" on the target computer.

- Change the Separator Return flow from 12 to 8 SLM (try 10 SLM on 2022-12-22).

Procedure for Resuming from the "Standby" Mode

- Change the Separator Return flow from 8 to 12 SLM, using "THCD_401_Main.vi".

- Wait for 5 minutes.

- This step is to accumulate LHe in the separator.

- Fill the nose with LHe manually. Can skip this step if the nose LHe level is already high, >70%.

- Set the turn of the bypass valve to "1.0", by entering the value to the "Set Turns" box (or clicking the up arrow of the box multiple times).

- Confirm that the Main Return flow increases on the right-side strip chart in this page; https://e906-gat1.fnal.gov/data-summary/e1039/target-par-preset/return_flow.php

- Increase the turn step-by-step (wait for 20 seconds per +0.1 turns), until the Main Return flow reaches about 50-80 SLM. Usually the turn should be 1.4-1.8.

- Wait until the nose LHe level becomes 80%. A higher level (80-100%) is acceptable, but never keep filling above 100%.

- If the level does not start going up in 5 minutes; close the valve, wait for 10 minutes, and try again.

- Close the bypass valve, by setting the turn to "0".

- Confirm that the Main Return flow is ~5 SLM or less, and the nose LHe level is going down slowly.

- Enable the automated control of the bypass valve.

- Confirm that the "Set Point of He Level" is 75%.

- Click the toggle switch labelled "Automated Bypass-Valve Control".

- Enable the SMS (Discord) alarm, by clicking the toggle switch labelled "SMS".

- Report on Discord that the automated control has started. Kenichi has to check the behavior at the beginning.

Hardware

- Motor: AM HT17-278 — https://www.applied-motion.com/products/stepper-motors/ht17-278

Motor driver: AM ST5-S — https://www.applied-motion.com/products/stepper-drives/st5-s

ADC: MCC USB-202

- Fridge valve control box

- ORC : Fridge valve control box.pdf

- Control box Wiring : Fridge Valve Box Wiring.PDF

- Mechanical information

- Run Valve : Run Valve Assembly

- Bypass Valve : Bypass Valve Assembly