Here are your 5 duties: Maintain Polarization, Maintain Cryogens, Move Target, Respond to Alarms, Log Everything.

Your first task on shift is to talk to the outgoing target operator and read the Fermilab elog! (https://dbweb8.fnal.gov:8443/ECL/spin_quest/U/login) Find out the following.

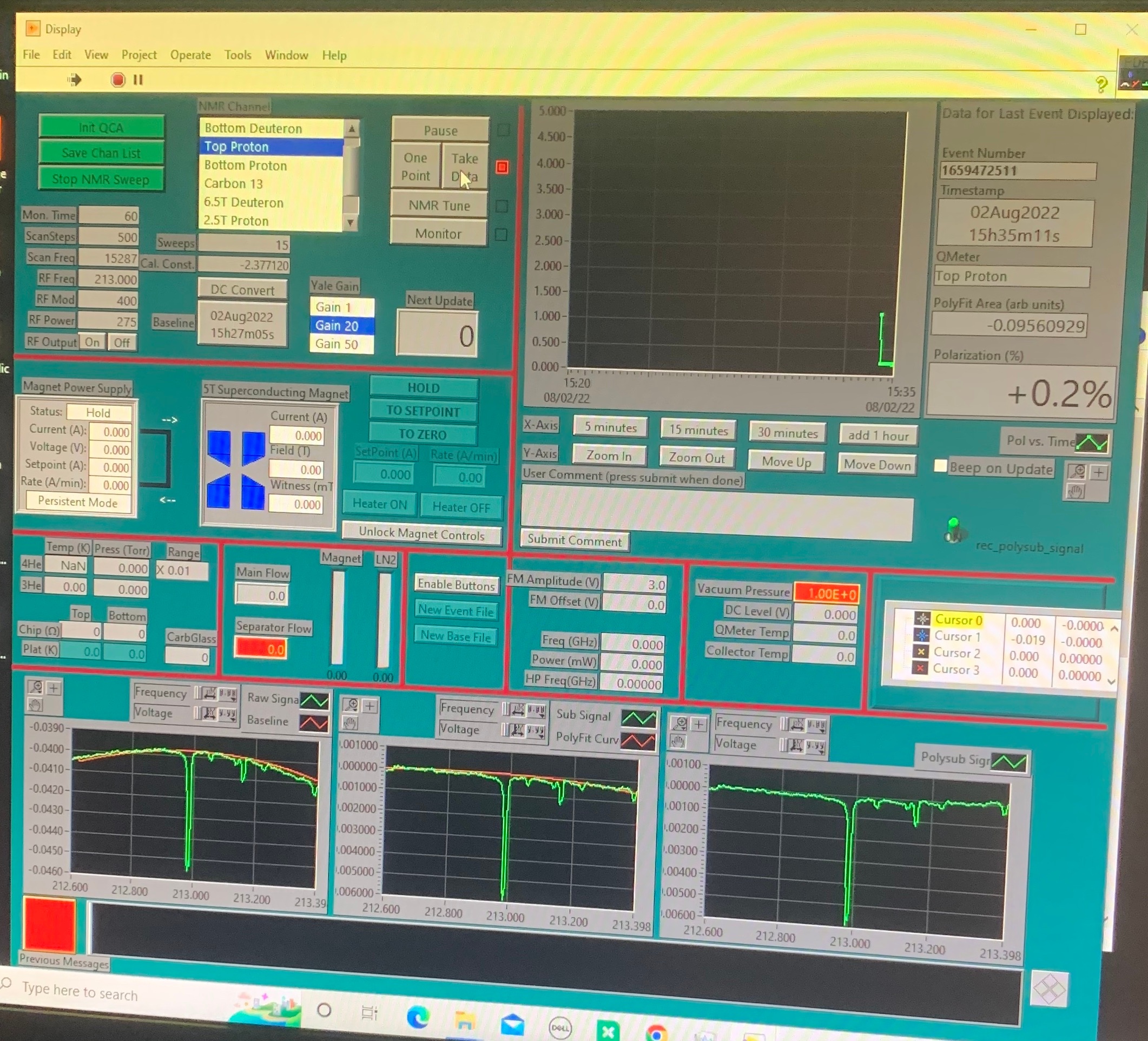

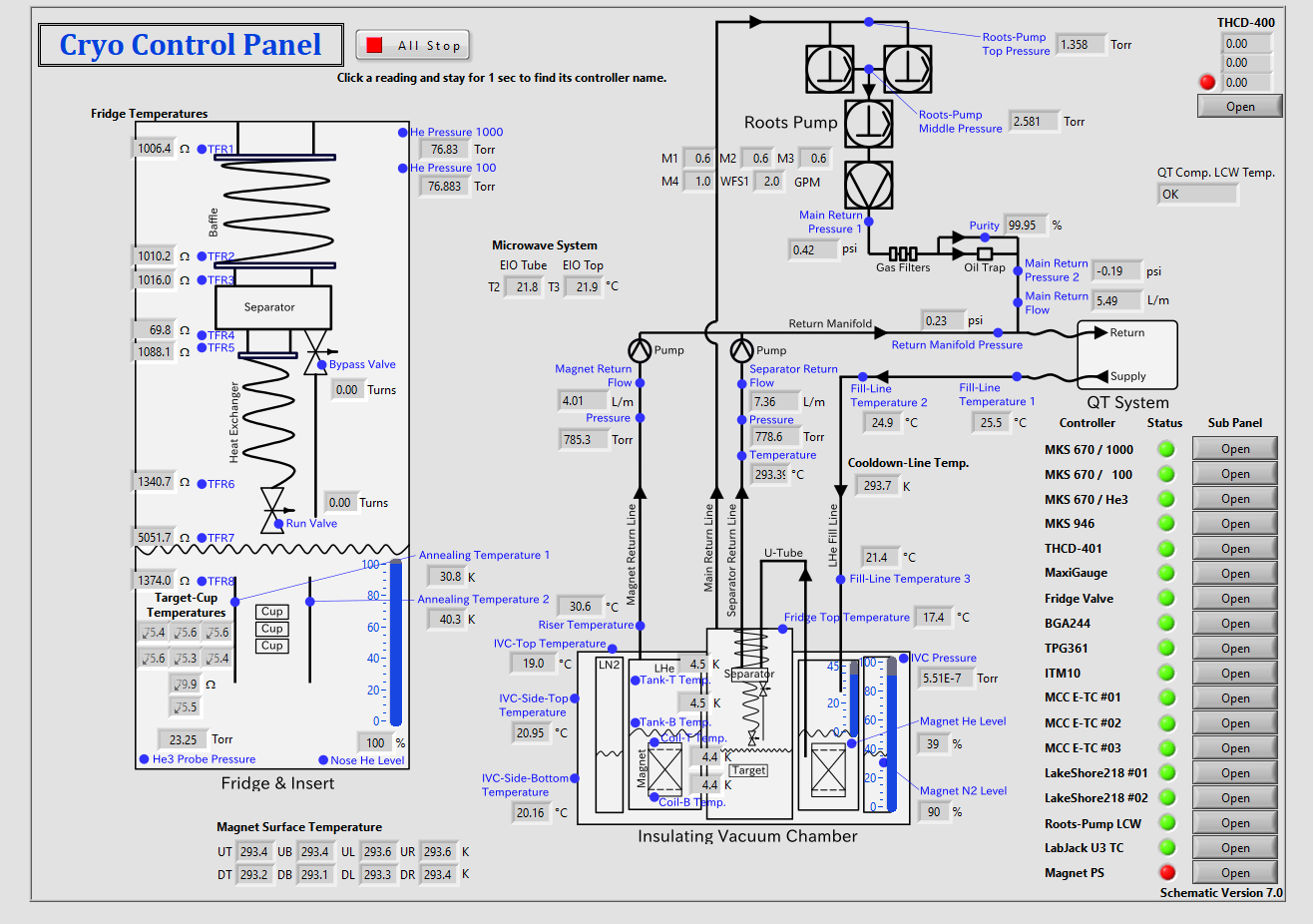

Next make sure all the necessary control screens are up. You should have PDP, the Cryo Controls, strip charts, and the alarm handler accessible.

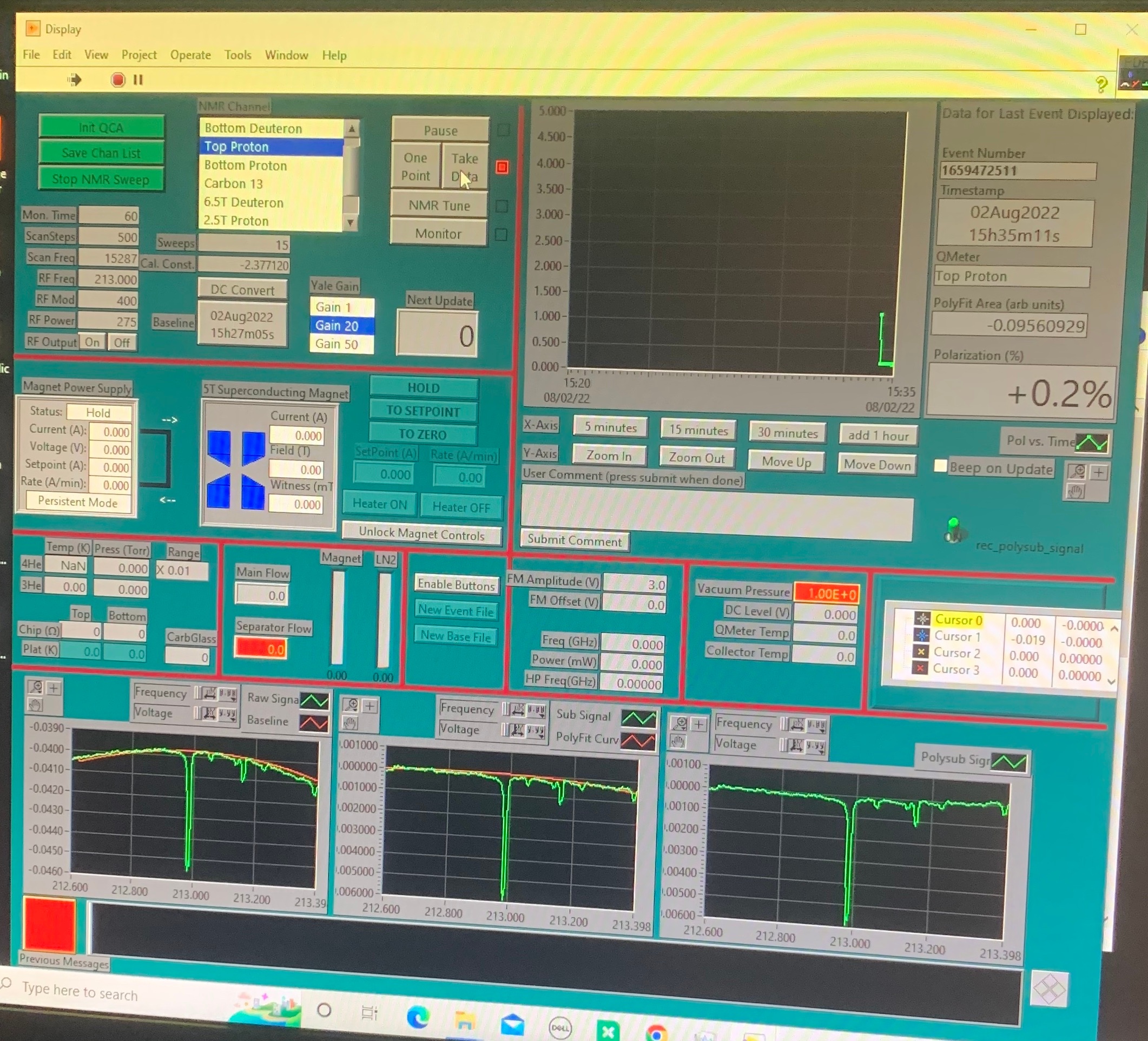

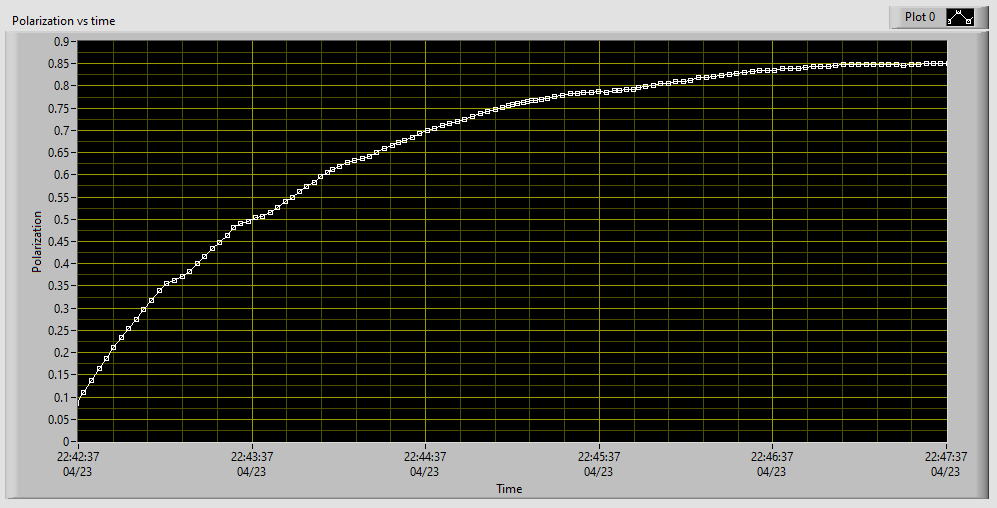

A good microwave frequency for the material will change as the material acquires dose. Thus the target operator is required to pay constant attention to the time evolution of the polarization and the microwave frequency.

The output frequency of the microwave is automatically controlled by the microwave VI. It takes the real-time polarization data recorded by the PDP via "Data input file".

Call the target expert if

The polarization is going down continuously for longer than 5 minutes.

| User Interface of Microwave VI | Example of Polarization vs Time |

|---|---|

|  |

The cryogens are maintained by automatic PID loops. Your job is generally to monitor these loops and step in if they fail.

If the level drops below a target cup, the polarization will drop to zero!

Ensure the levels stay within alarmed levels. If they drop too low or go too high, wait to see if the alarms go away. If they don't contact a target expert.

| Space | ID | Low | High | Fill Procedure |

|---|---|---|---|---|

| Magnet LHe | manifolds Magnet Dewar Level | 10% | 45% | https://seaquest-docdb.fnal.gov/cgi-bin/sso/ShowDocument?docid=9670 |

| Magnet LN2 | LL106-N | 40% | 90% | https://seaquest-docdb.fnal.gov/cgi-bin/sso/ShowDocument?docid=10337 |

There are 4 levels to watch

Magnet LHe level: This LHe level should always be > 10% during the operational state. Monitor the level and arrange re-fills in a timely manner.

Note: Maximum level of the magnet is 45% due to the geometrical positioning of the level probe in the magnet.

Purifier liquid nitrogen (LN2) level: This LN2 level should always be > 50%. Monitor the level and arrange re-fills in a timely manner.

Storage tank (gHe) pressure: This should be between 40 PSI and 110 PSI.

If the pressure reaches 110 PSI, then you will need to arrange to vent gHe to the atmosphere.

Use this procedure: https://seaquest-docdb.fnal.gov/cgi-bin/sso/ShowDocument?docid=10285

If the pressure is reaching 40 PSI, you will need to arrange a re-fill of gHe ahead of time. Please contact Kun Liu for a re-fill.

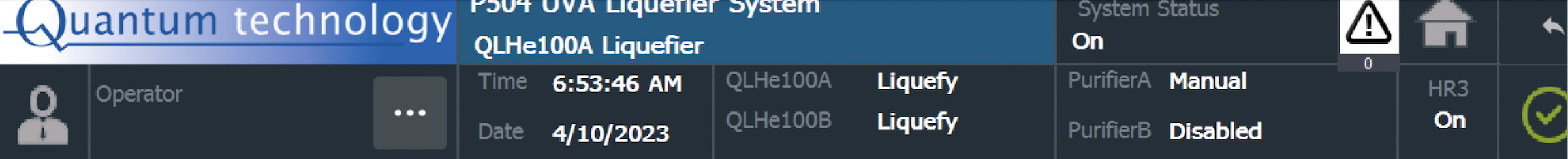

QT System

Set of slides with operational settings: QT_Operational_Settings.pdf

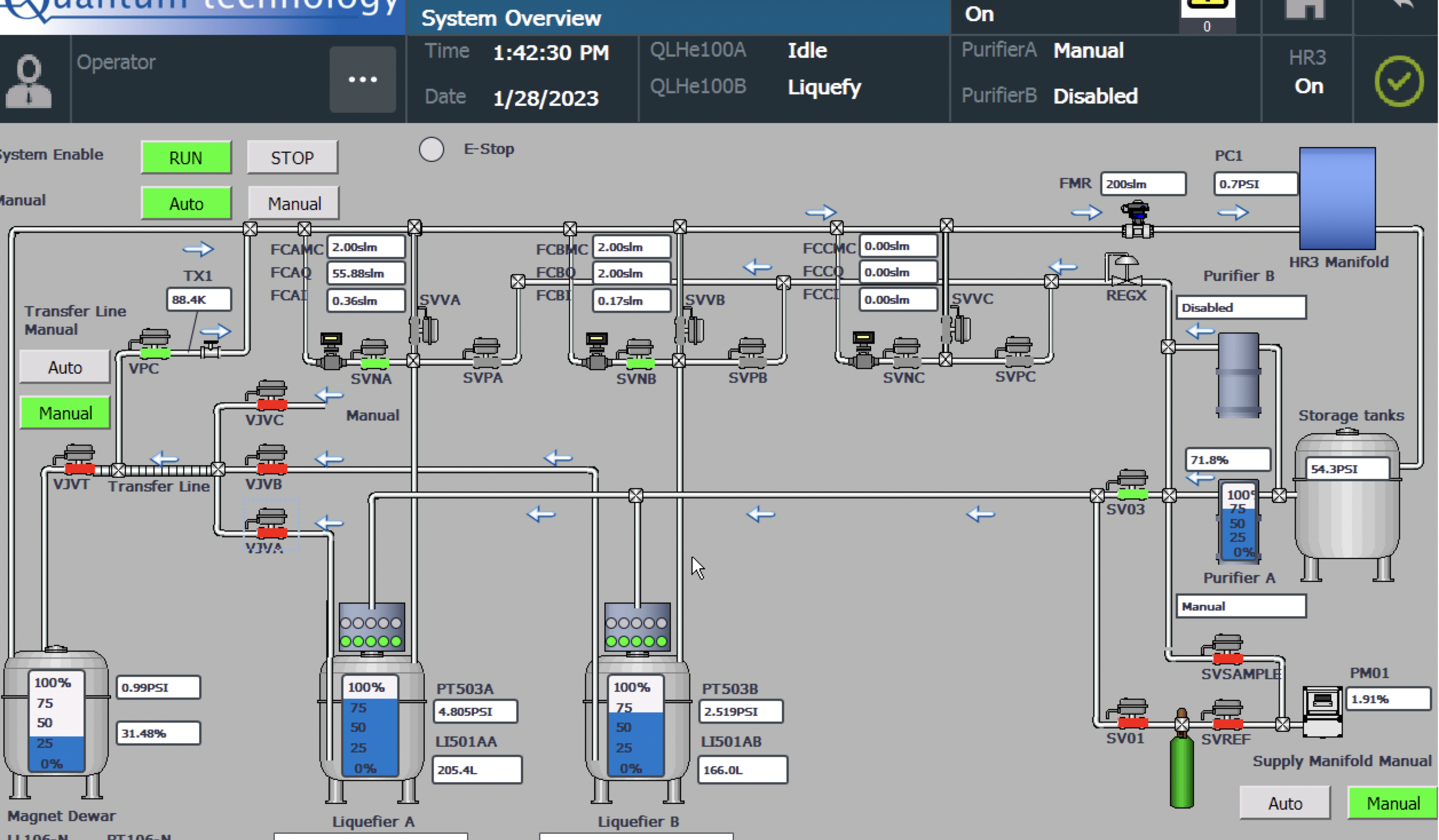

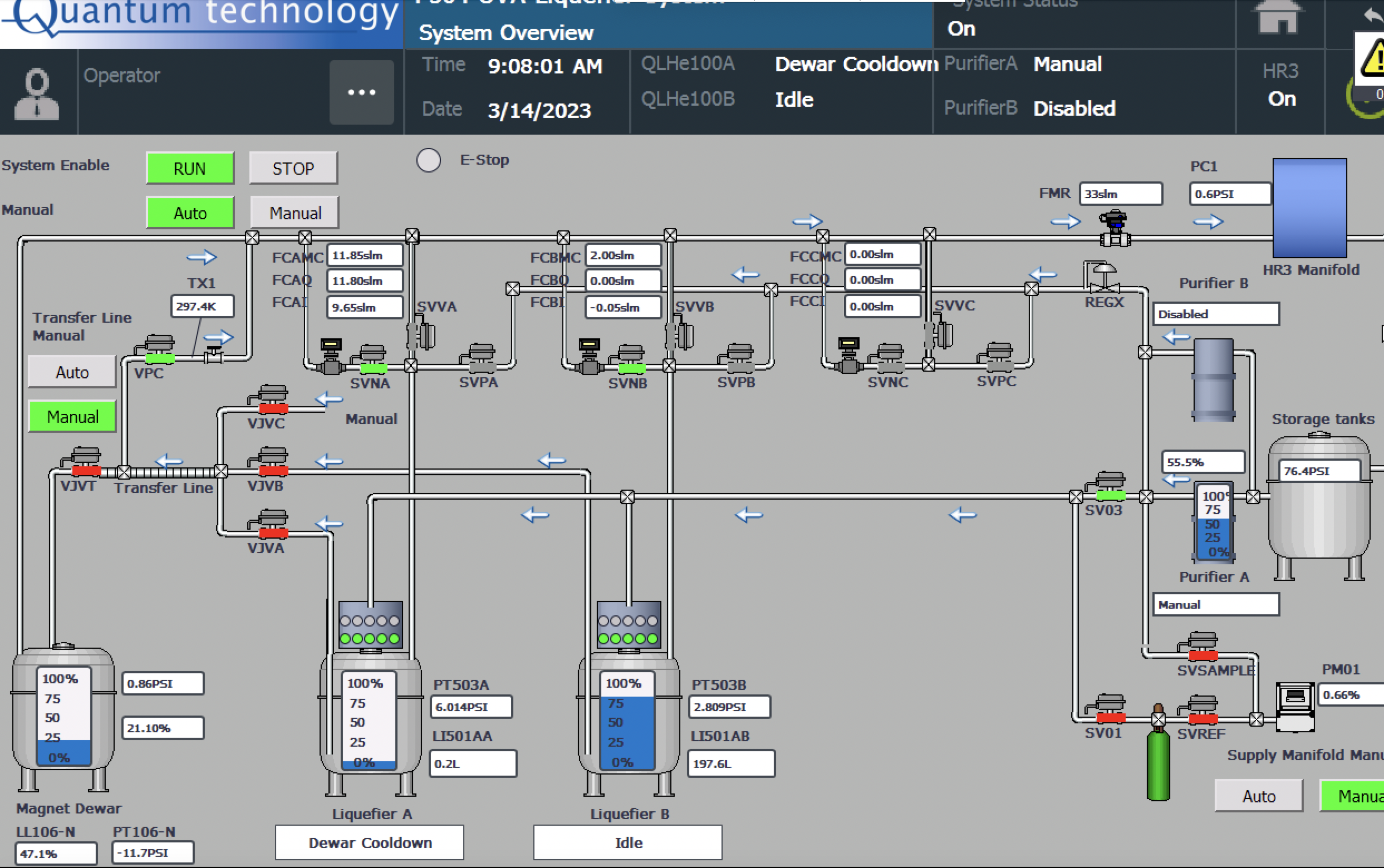

The first thing (on the UVA-QT system) to check is the overall status of the system on QT-HMI, and the main part of the screen is the following.

System status: "ON"

Both Liquefiers: "Liquefy" mode (or could be either "Cooldown" or "Manual" mode depending on the current conditions different from "Liquefying").

Purifier A: "Manual" mode

Purifier B: N/A (we don't have a purifier B)

HR3: "ON" + Green check mark.

If you see "Alarm" on any of those status indicators (in the above picture), then that needs to be addressed/fixed soon.

If that's the case, coordinate with the Target Expert on shift to fix those.

The overview screen (example)

This example picture illustrates that both Liquefiers are "ON". Liquefier A is in "Idle" mode, whereas Liquefier B is in "Liquefy" mode.

("Idle" mode means, the Liquefier is just holding liquid helium at ~4 K but not producing).

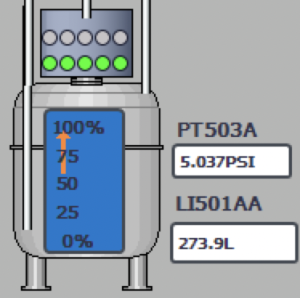

Also, you can monitor the LHe, LN2 levels in the magnet, as well as the LN2 level in the purifier as well. Another example image is below.

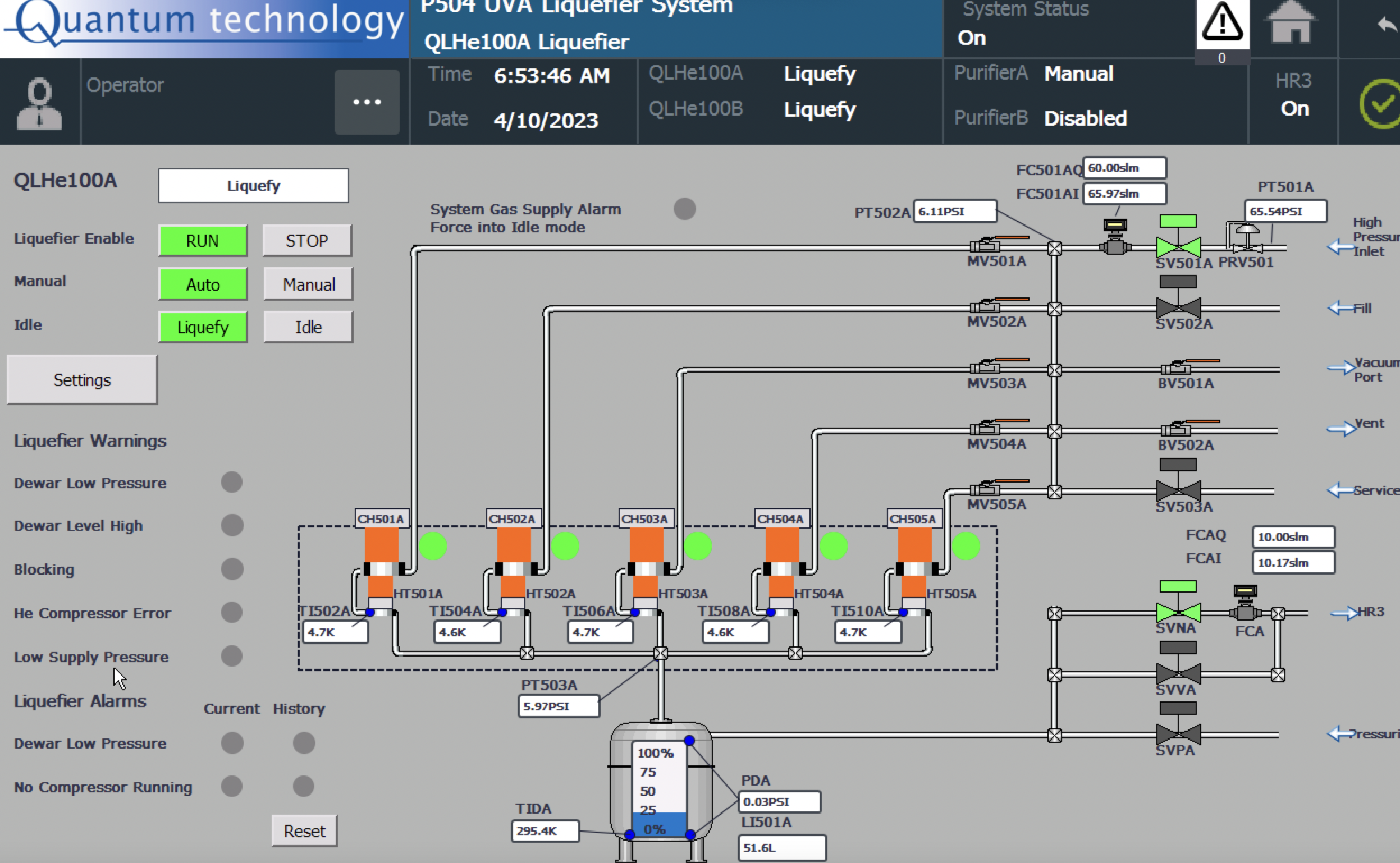

Check each Liquerfier screens (A & B) at least once per hour. A sample operational screen is below.

The main components to check on the Liquefier screens are below:

1) Mode (top left): Should be Run + Auto + Liquefy mode if it's in the production mode

2) Cold head temperatures: Should be around > 3 Kelvin.

3) Make sure the Liquefier is producing LHe and the Dewar level keeps increasing (~4L/hr in average)

If you start seeing large frequent fluctuations (similar to the following image).

It may be an indication that the Dewar level sensor tubes are contaminated. Please contact the Target Expert on shift immediately.

Procedure for cleaning the tubes: https://seaquest-docdb.fnal.gov/cgi-bin/sso/ShowDocument?docid=10401

4) Make sure FC501(A/B)I (actual inlet gHe flow) is close to FC501(A/B)Q (gHe set-flow from PID) (see "Settings" screen to check the set values)

5) Make sure FC(A/B)I (actual outlet gHe flow) is close to FC(A/B)Q (gHe outlet set-flow from PID) (see "Settings" screen to check the set values)

In terms of the UVA-QT system maintenance, we need to keep the LN2 levels in the purifier always above 50% for higher production rate.

| Fill Procedure | Procedure |

|---|---|

| Filling LN2 to the purifier (remote: using the outside LN2 tank) | https://seaquest-docdb.fnal.gov/cgi-bin/sso/ShowDocument?docid=10337 |

| Filling LN2 to the purifier (in-person: using a portable LN2 Dewar) | https://seaquest-docdb.fnal.gov/cgi-bin/sso/ShowDocument?docid=10053 |

It is a LabVIEW program (VI) that controls and monitors all cryogenic devices (except the QT Liquefier System). It is running on the target computer.

The target operator

Main Panel of CCP

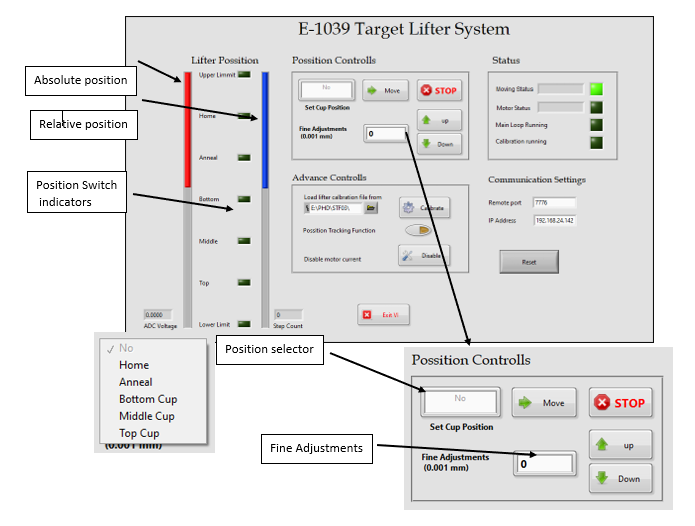

The position of target cells is controlled by moving the target stick via the Target Lifter VI on the target computer. The run coordinator schedules the next target move.

The target operator moves the target at the scheduled time, by following the instructions below. If the Target Lifter VI shows any error or causes any unexpected condition, please call the target expert.

Make sure what is the destination location (i.e. "home", "annealing", "bottom", "top" or "middle").

Select the destination label from the drop-down menu in the Target Lifter VI.

Press “move”. Confirm that the red and blue progress bars update accordingly.

Keep eyes on the corresponding position switch indicator on the VI.

It will illuminate and stop the motion by itself.

If you see the progress bars update beyond the desired location, press the "STOP" button to stop the motion immediately, and call the target expert.

User Interface of Target Lifter VI

There are 2 NMR coils, one in the Top cup, one in the Bottom.

The target operator responds to all alarms that appear on the QT HMI, the Cryo Control Panel, the Microwave VI, the Target Lifter VI and the PDP. There are two levels of alarms;

An instruction on each alarm can be found in the documentation on the corresponding subsystem page. Call the target expert if you cannot find it.

After filling the LN2 (liquid Nitrogen) in the purifier, the magnet shield, the LHe (liquid helium) to the Magnet space, and the fridge space should be recorded on the FNAL elog (https://dbweb8.fnal.gov:8443/ECL/spin_quest/U/login). Each filling should be recorded on the FNAL ECL by creating a new Entry under the Target category and followed by approved procedures. Some target-related elogs pattern is listed below:

Entry Subject: Filled the purifier using LN2 outside tank

I filled the purifier using the LN2 outside tank, following the procedure on docdb #10337 (by Jordan Bohn).

LN2 Tank level = 37 inwc

LN2 Purifier = Starting time=15:38, Starting level=63.0%, Finish time=15:59, Finish Level=91.0%

In the above Elog, the Purifier is filled with LN2 using the approved procedure using the outside LN2 tank. Before filling the purifier, look at the LN2 tank manual gauge. For filling the purifier, the LN2 tank should be above 10 inwc. These instructions are listed on the procedure on docdb #10337.

Entry Subject: Filled the magnet shield using LN2 outside tank

I filled the magnet shield using the LN2 outside tank, following the procedure on docdb #10337 (by Jordan Bohn).

LN2 Tank level = 30 inwc

LN2 Magnet shield= Starting time=16:38, Starting level=55%, Finish time=17:00, Finish Level=91.0%

In the above Elog, the magnet shield is filled with LN2 using the approved procedure using the outside LN2 tank. Before filling the magnet shield, look at the LN2 tank manual gauge. For filling the magnet shield, the LN2 tank should be above 10 inwc. These instructions are listed on the procedure on docdb #10337.

Entry Subject: Filled the target fridge with LHe

I filled the target fridge with LHe

* From nose level = 0% at 15:01

* To Heat-Ex Top at 16:13.

Before filling the fridge space with LHe, we do not need to manually open the gate valve bypass valve because we are working on the remote gate valve bypass valve. We will swap out the manual gate-valve bypass valve with a remote gate valve. The approved procedure is on DocDB# 10375.

Entry Subject: Fill the magnet with LHe using QT Dewar

We filled the magnet up to 45% (145 L) with LHe using QT Dewar B and maintained the coils' temperature at 4.4K.

Today's transfer efficiency was 65%.

In the above FNAL elog, the choice of the QT Dewar A/B and how to calculate the transfer efficiency are listed on the procedure on docdb #9670.