On we started the Liquefier A after cleaning up the Dewar A level sensors using the procedure (docdb). According to the procedure, the bottom tube did not vent gHe on when the cold head temperatures are slightly above 240 K. So, we had to wait until all the cold heads are above 272K.

Since then (03/06/2023), Dewar A wasn't producing liquid until the 03/19/2023 afternoon. Below is the log of things that we did.

Around 11:26am on 03/12/2023

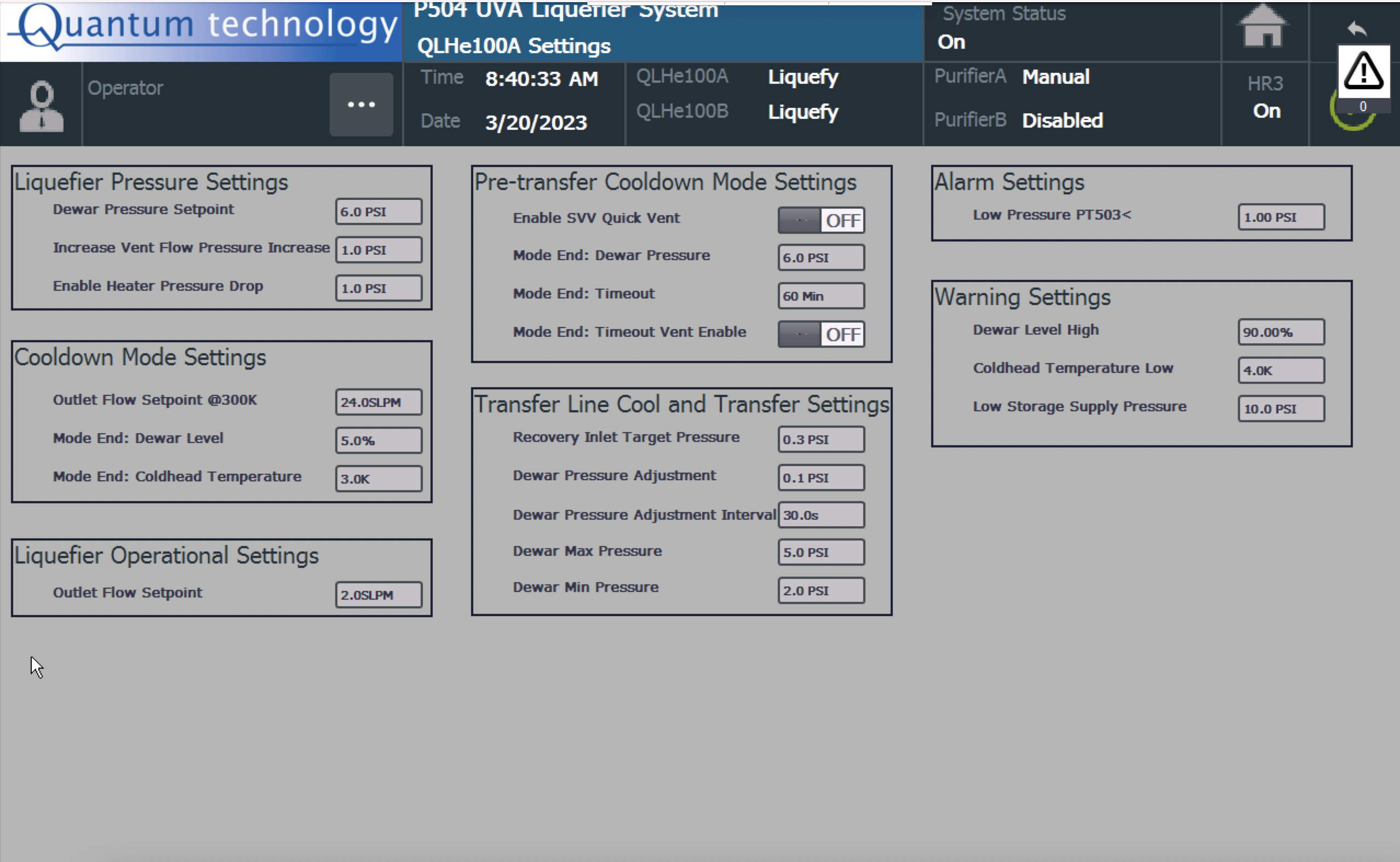

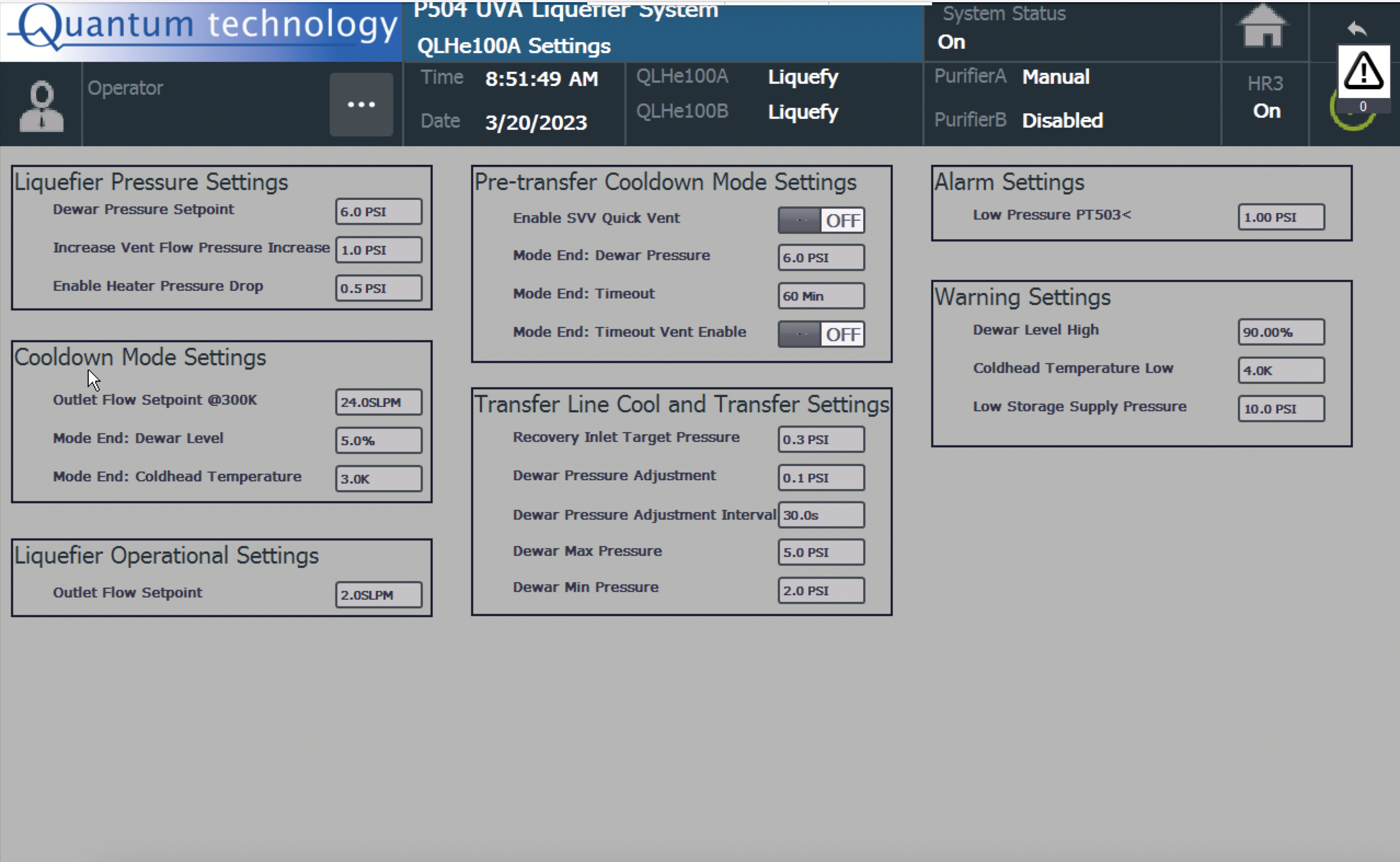

1. Set the "Mode End: Coldhead Temperature" to 3 K

2. Had to switch the LQ-A to the Manual mode for a minute and the switched back to Liquefy mode to enable the change made in the previous step.

3. See the cold-head temperatures since 03/06/2023.

4. Flow change after making the change on Mode End: Coldhead Temperature" to 3 K.

On 03/14/2023

LQ-A is still the same, LI501 shows 0.2 L. Adam suggested changing the outlet flow to 24 slm and I just changed it on the LQ-A Settings screen.

The issue was that, the FCAI hasn't go up beyond ~8slm although FCAQ is set to 24slm.

Then, on 03/14/2023 around 4:20pm CST, we closed the NV501A needle valve as Adam suggested, to improve the Liquefaction on LQ-A. It was between 1/4 and 1/2 a turn opened position before it was completely closed.

Initial position Completely closed position

On 03/15/2023 around 2:20 pm

We opened the NV501A needle valve by two full turns from the current setting(fully closed position) as Joey (QT) recommended.

On 03/16/2023

1. In addition to the 2 turns (open) on 03/15/2023, NV501A was opened with one more full turn.

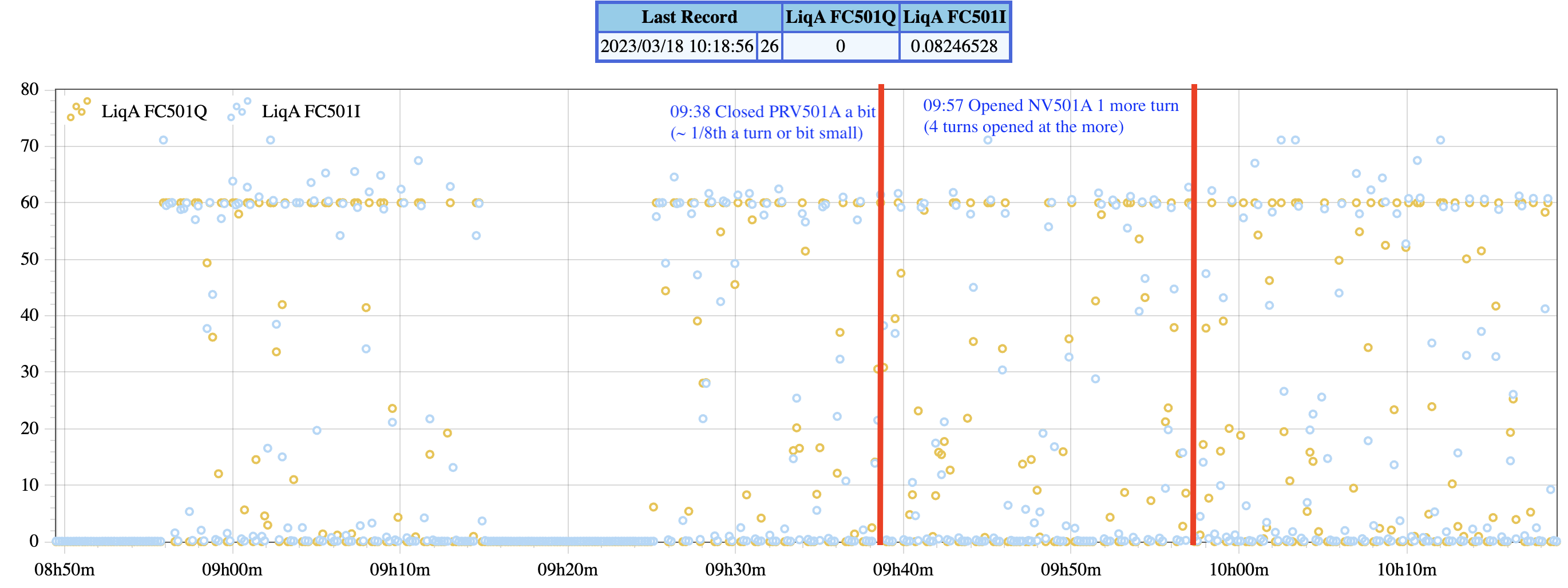

2. We adjusted the PRV501A, in order to obtain a smooth inlet flow.

(Initial Position) (Final Position)

* We noticed that it takes about ~10min response time after changing PRV501A.

On 03/18/2023

In addition to the 3 turns (open) since 03/16/2023, NV501A was opened with one more full turn.

PRV501A was opened slightly a bit (~1/8th of a turn).

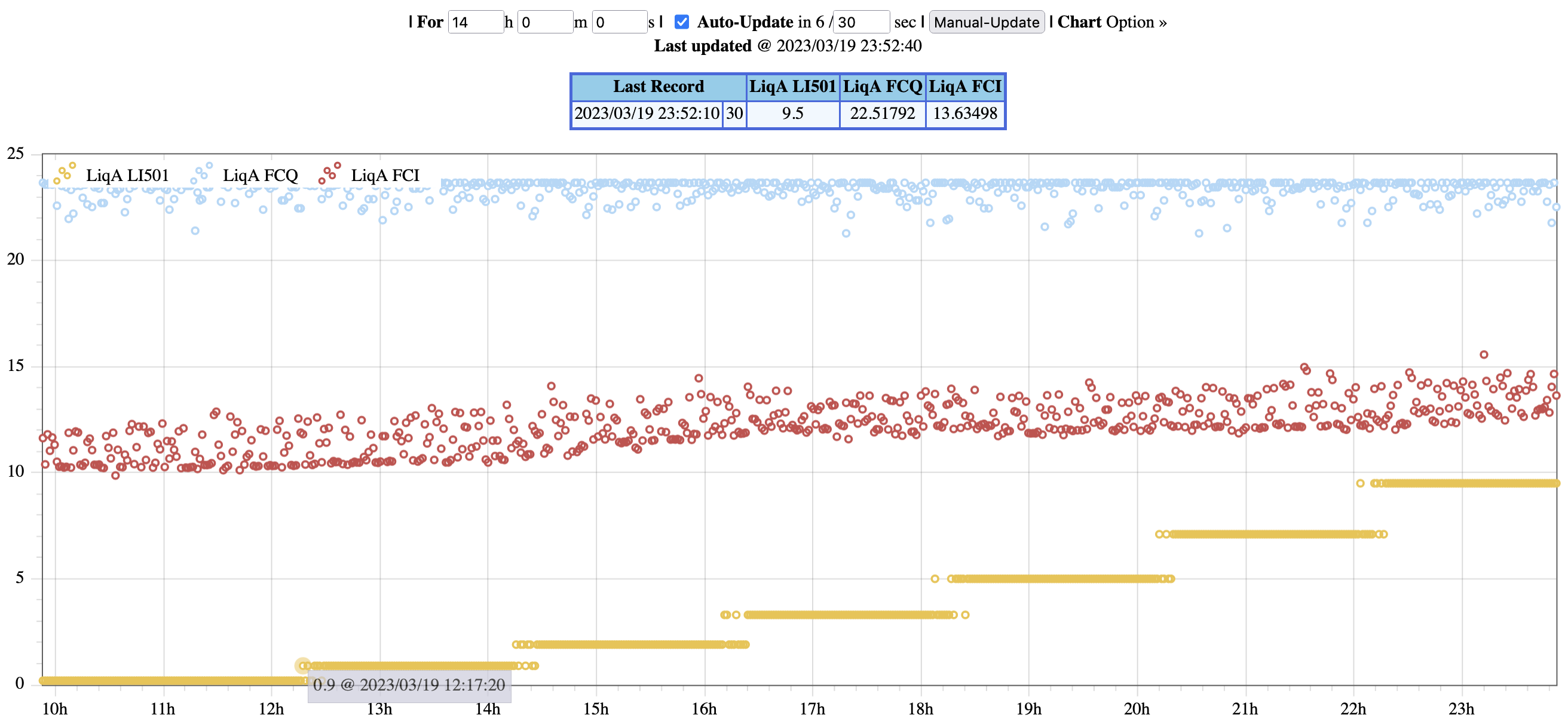

On 03/19/2023

After 13 days of starting the Cooldown of the Liquefier A, today the level sensor indicated that the Dewar A has started accumulating liquid. Notice that the outlet flow actual value is around ~13slm although FCAQ is still set to 24slm.

On 03/20/203

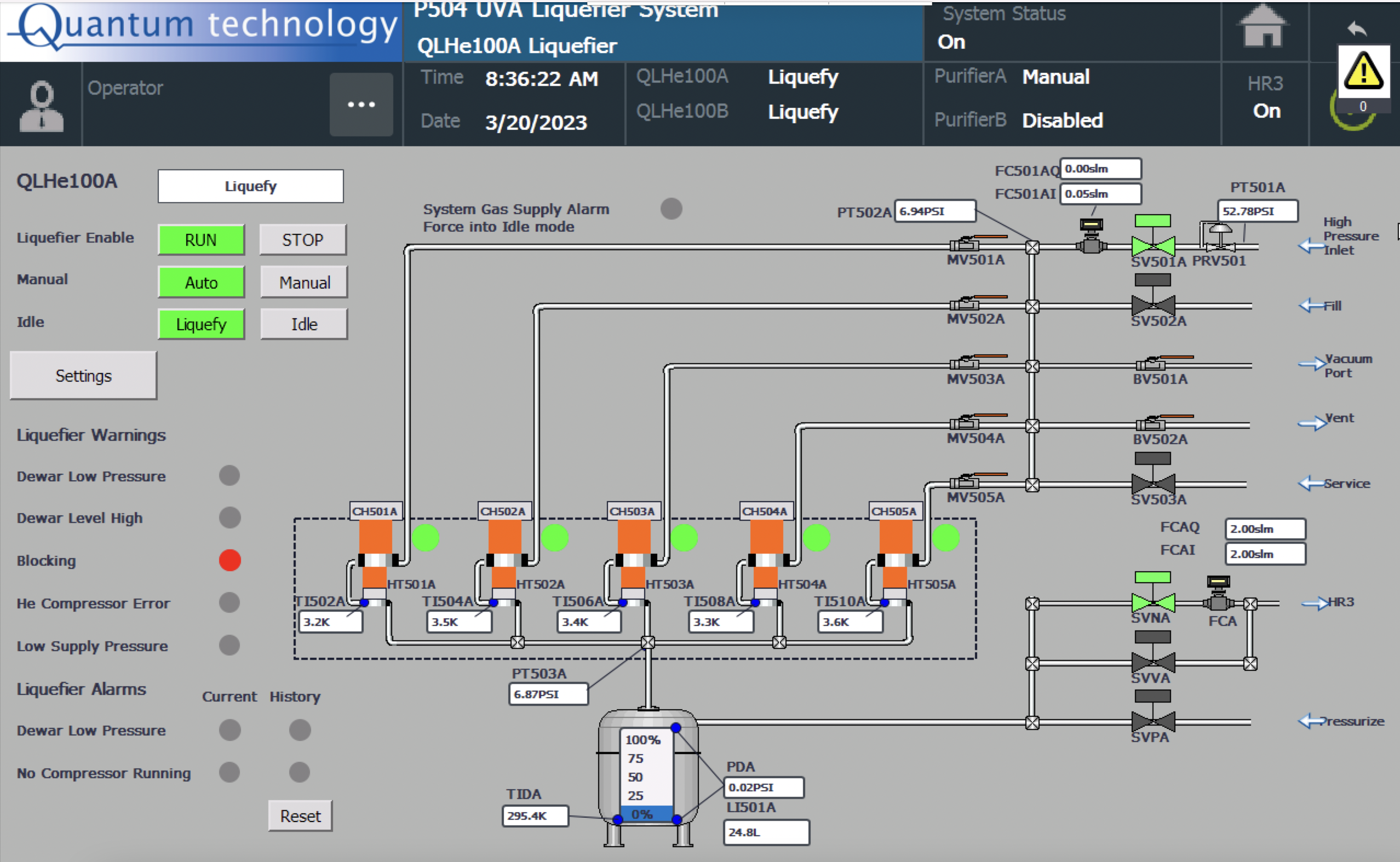

In the morning we noticed that the Liquefier A switched to the "Liquefy" mode automatically because the condition "Mode end: Dewar level" 5% was met.

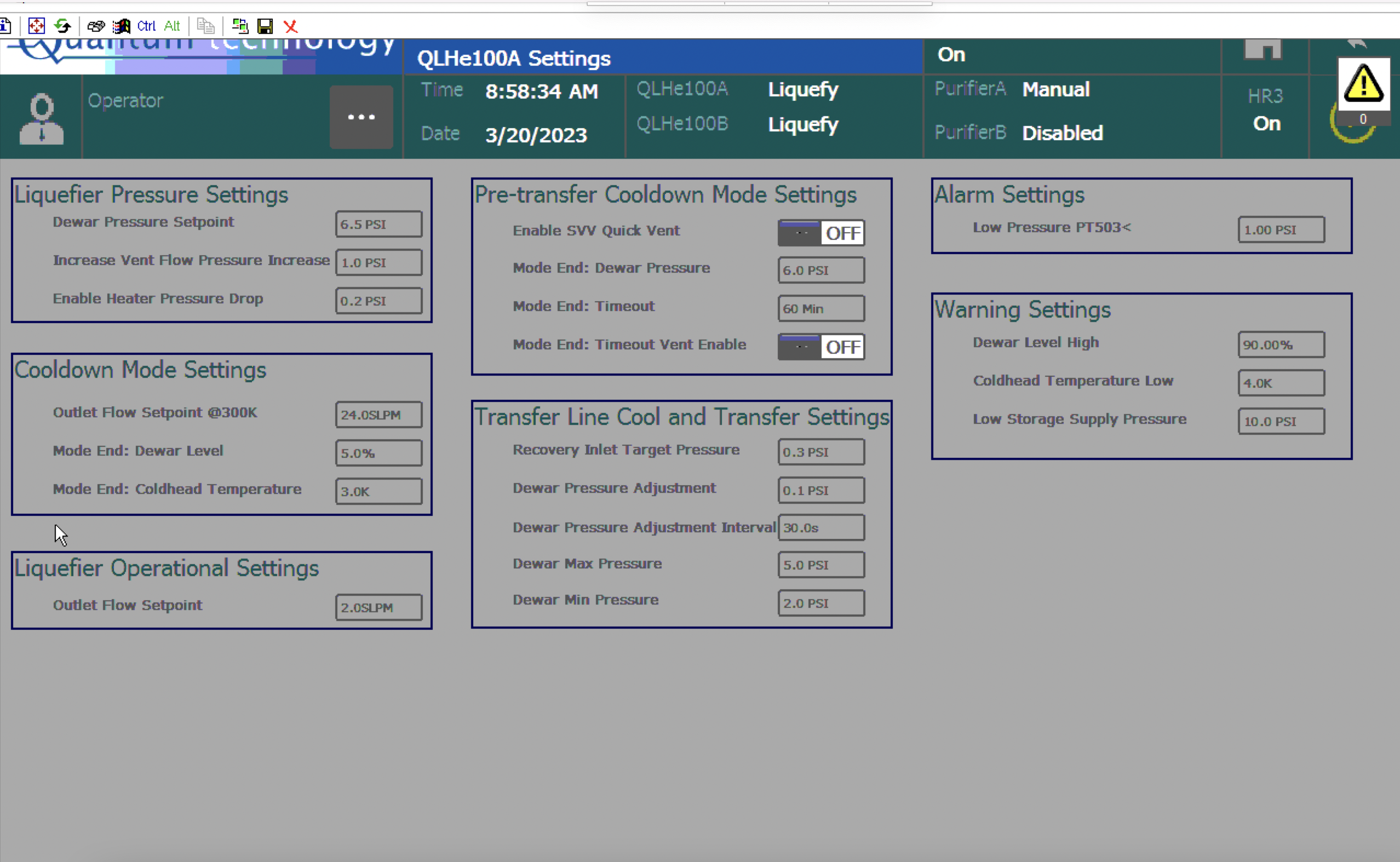

The liquid level is ~24L and artificial blockage appeared. So, the Dewar pressure and heater were adjusted to get rid of the blockage.

(Before) (after)

A screen video of Liquefier A

Dewar Cooldown Mode:

Historically we have had more trouble with cooling Dewar A down than Dewar B. Dewar A has taken more than 3 days in the past and this most recent time (March '23) its taken about two weeks.

This is likely just because the settings were not optimized for cooling and we had better pay more attention to the system setting for switching between production and cooling modes. If the pressure in the dewar is greater than that on the cold heads the dewar will never cool and the system enters a perpetual state where the cold heads are cold but the dewar is warm.

It seems that the green-handled regulator on the QT manifold should not be open too much. This will make the MFC letting in the helium to the cold heads fluctuated a lot which is not optimal for cooling. During cooldown mode you want a large flow running in and out of the dewar with the goal of around 60 slm going in and 24 slm going out. In order for this to work the pressure in the cold heads much stay slightly above the dewar pressure so flow continuously runs to the dewar to cool things down. The black-handled needle valve should be open a lot (maybe all the way) to keep the flow through this area as high as possible. This will lead to lots of frost and ice build up on the dewar neck. This should not be a problem but should be checked and defrosted regularly. When everything is set appropriately the accumulation of liquid should happen in about 24 hours.

Cooldown Mode Settings

- Open the NV501 (A/B) as much as it doesn't affect producing a lot of ice on the Dewar neck. This will allow a higher flow circulation between the Dewar and coldheads.

- In the "Cooldown Mode Settings": Set the outlet flow to 24slm and End mode cold head temperature to 3K

- Reduce PRV501 (A/B) (green-hand valve) to barely provide the flow that FC501(A/B) flow controller asking for.

Liqefy Mode Settings

1. Close the NV501 (A/B) until there is no ice accumulation on Dewar neck

Questions

a.) Is there a downside to having the needle valve open too much during the dewar cooldown?

b.) Are the seals at the top of the neck something we should try to keep warm or will this run into contamination issues?

c.) Do we understand why the overfilling (just up to 220L) leads to this contamination issue? Can this be fixed with different tubing?

With past experiences, the level sensor's large fluctuations happened if the Dewar was kept full ( > 210 L) for more than two or three days.

d.) How to adjust the outlet flow while in the Liquefy mode? (without going to the manual mode)

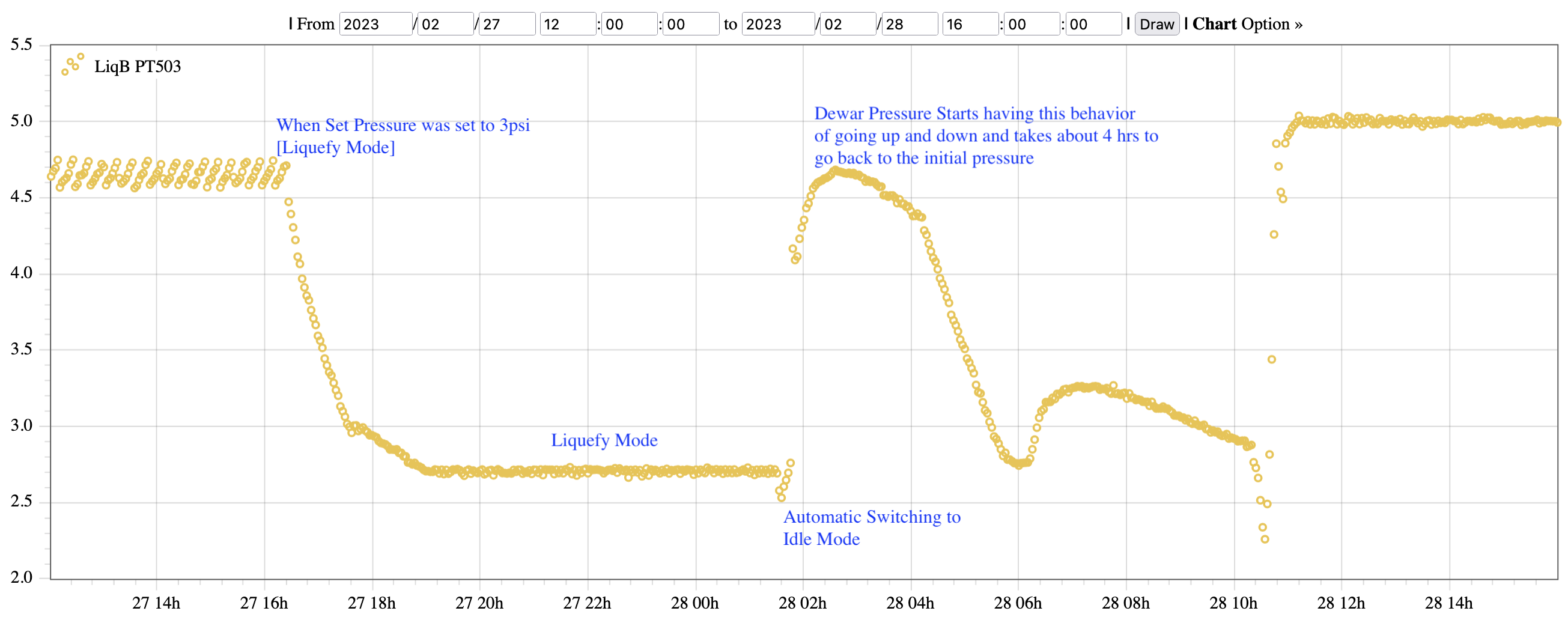

Especially, when we want to bring down the Dewar pressure for a fill (like from 5pi to 3psi), it usually takes about 5 hrs. How can we improve that?

By experience, we noticed in the past, if we use higher flow using the bypass SVVA/B, those solenoid valves got stuck-open, and we will have to avoid that situation too.

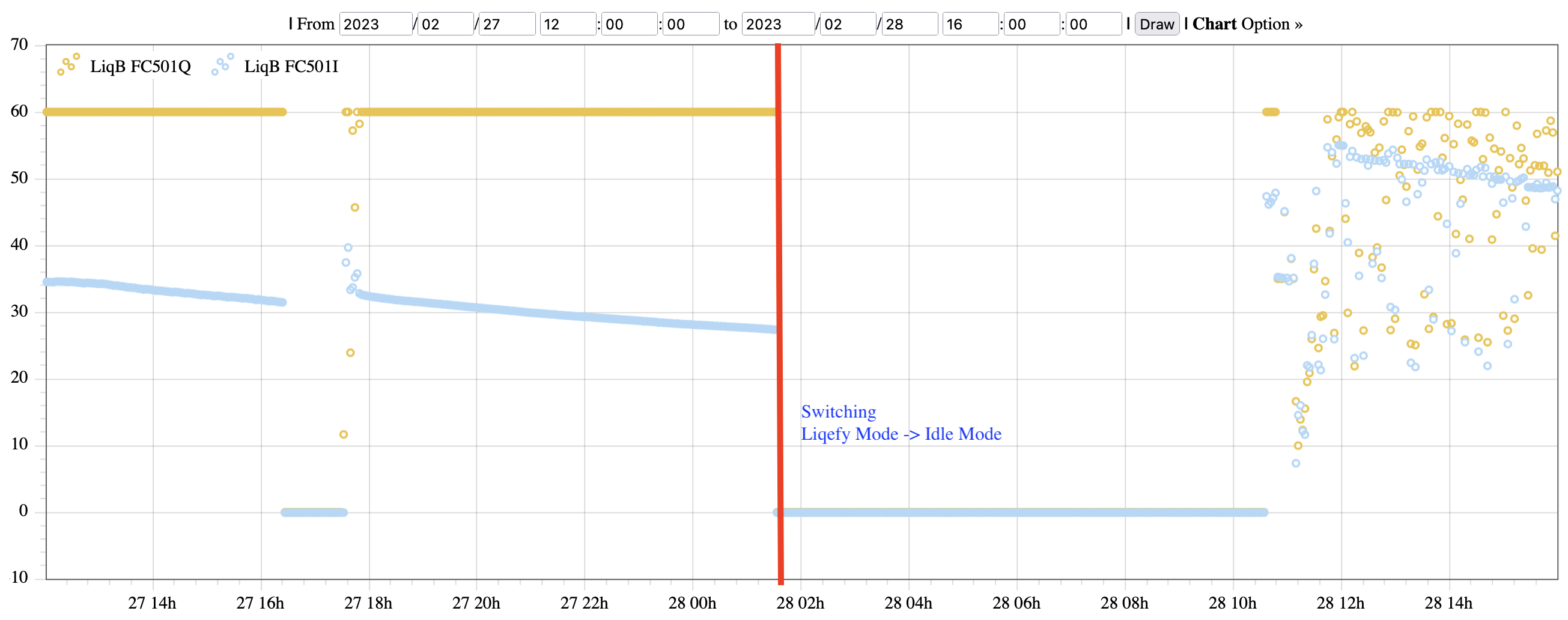

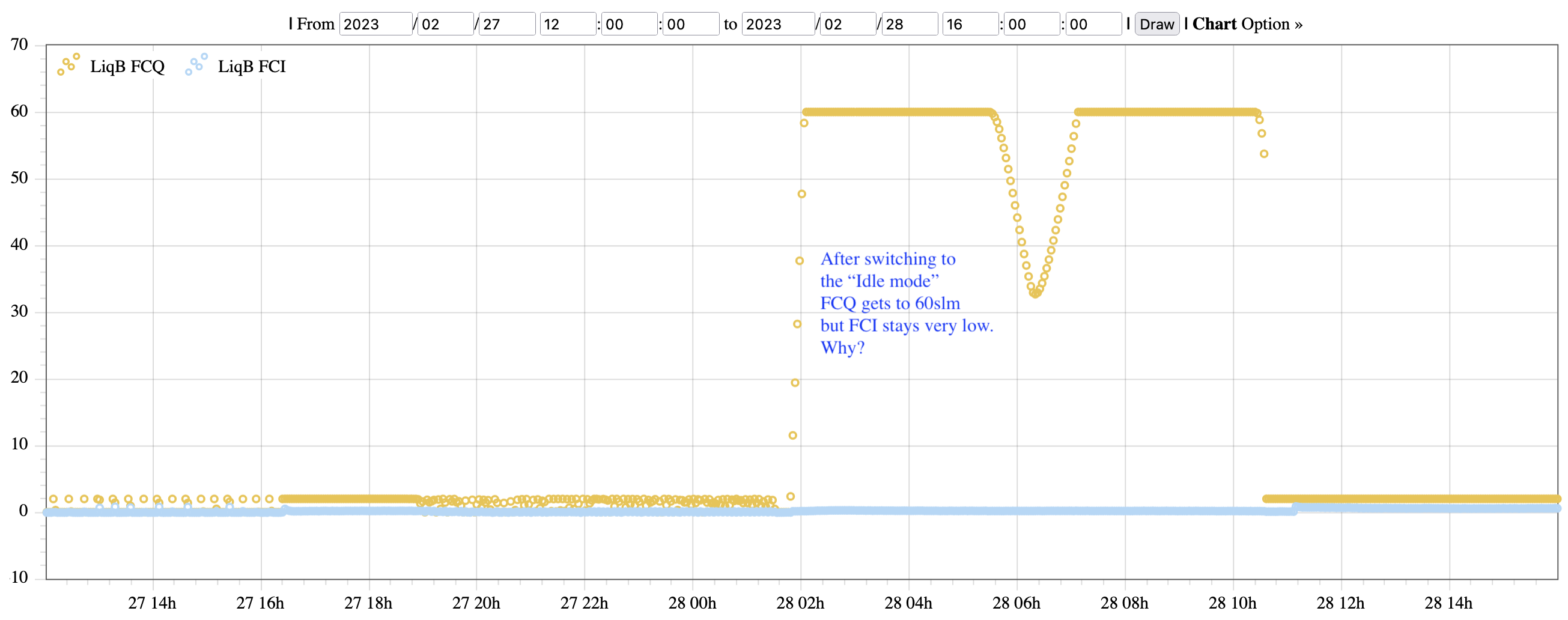

e.) Why Dewar pressure, inlet/outlet flows start behaving like the following when it was switched to the Idle mode (either by automatically or manually)?

e.) Purifier is still in Manual mode since the beginning, any plans to enable the "auto" mode?

We noticed that once the Liquefiers are accidentally go to "Stop" mode, the v9 and v21 solenoid valves get closed.

f.) Calibrations of

(i) FMR : This was done by Sam by applying a conversion equation with the characteristic parameters for gHe.

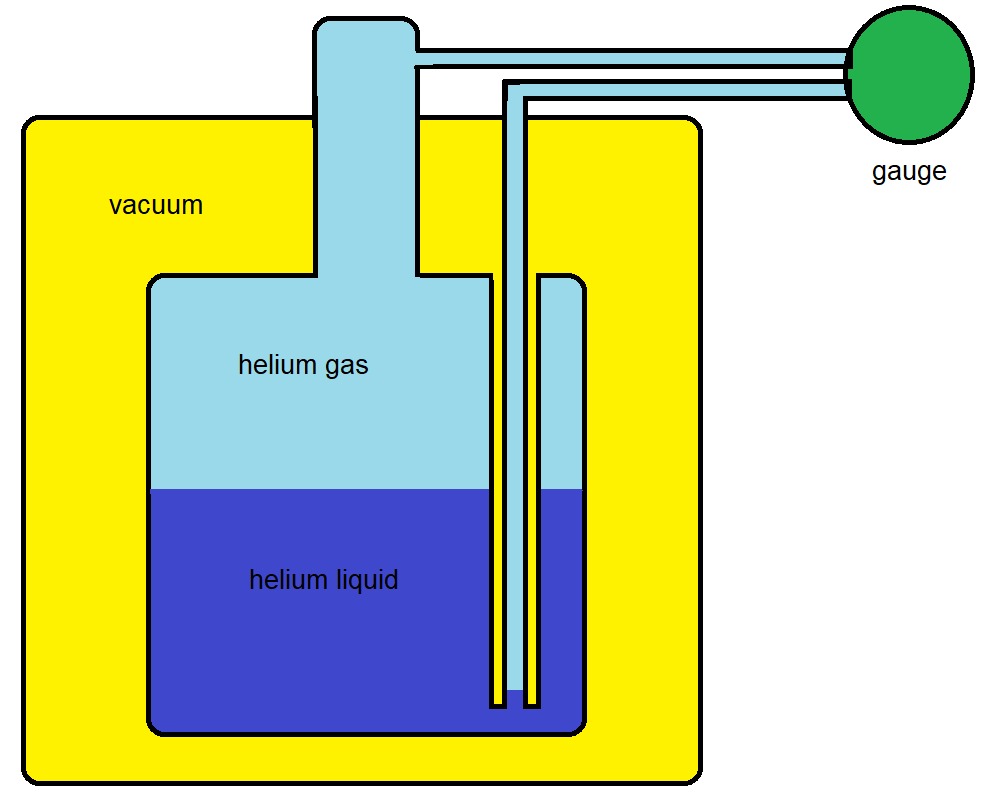

(ii) Dewar Level sensors: We can adjust this by comparing with the manual gauges

g.) PT8:

It seems that this pressure sensor is accurate at high pressure but has about ~15psi off when it's below 50 psi.

Sam recommended this product (the same one): https://www.automationdirect.com/adc/shopping/catalog/process_control_-a-_measurement/pressure_sensors/pressure_transmitters/sptd25-20-0300h