Here are your 5 duties: Maintain Polarization, Maintain Cryogens, Move Target, Respond to Alarms, Log Everything.

Your first task on shift is to talk to the outgoing target operator and read the Hall A Log! Find out the following.

- What target are we on?

- What is the calibration constant and baseline we are using?

- What is the encoder position for that target?

- What frequency has provided the best polarization?

- What alarms have occurred? How have they been addressed?

- Is anything else different about the target today?

- What target are we on?

- Next make sure all the necessary control screens are up. You should have PDP, the Cryo Controls, strip charts, and the alarm handler accessible.

Maintain Polarization

The polarization should be your constant worry. Even once you've found a good microwave frequency for the material, be vigilant! This frequency will change as the sample acquires dose!

Your constant attention to the microwave frequency is required! Change it often to ensure you have the highest polarization!

NMR

- The NMR system is how we monitor the polarization. Read the PDP overview for a tour of the software we use for NMR.

- "Take Data" to run the NMR, and hit "DC Convert" when you need to recenter the signal.

Microwaves

- Adjust the microwave frequency using the bellows (to the left of the target computer).

- Monitor the frequency you set using the monitor on the EIP frequency counter on the camera.

- Wait a few updates to see how your adjustment has affected the polarization. Write down the effects in the logbook.

- Continue to adjust to maximize the polarization. Write down the best frequency in the logbook.

The frequency at which the material best polarizes will change over time during the run. You must constantly adjust the microwave frequency to optimize polarization.

Maintain Cryogens

The cryogens are maintained by automatic PID loops. Your job is generally to monitor these loops and step in if they fail.

Nose Level

- Keeping the Liquid Helium above the targets is crucial.

If the level drops below a target cup, the polarization will drop to zero!

- With both the beam and microwaves on, there is a large heat load evaporating helium.

- A PID loop should automatically adjust the run and separator valves to maintain appropriate levels.

- If the PID loop is not working, it is your job to adjust the run and separator valves to keep the target running.

- If the liquid level probe is not working, you can use the platinum resistors readings in PDP.

- Use the flows out of the fridge to anticipate changes in liquid level.

- The separator flow (FI91127) is usually good around 5-10.

- The main flow (FI91148) will change with the heat load of microwaves and beam. With both on, 20's is good.

- Keep the separator flow higher than the fridge flow in most cases.

- These values are guides, and may not always be best for all situations.

Magnet Liquid Level

- The magnet helium and nitrogen levels are controlled automatically.

- Ensure the levels stay within alarmed levels. If they drop too low or go too high, wait to see if the alarms go away. If they don't contact a target expert.

There are 4 levels to watch

- Magnet Helium (LL91111)

- Magnet Nitrogen (LL91110)

- Buffer Dewar Helium (LL91101)

- Nose Level (LL91112)

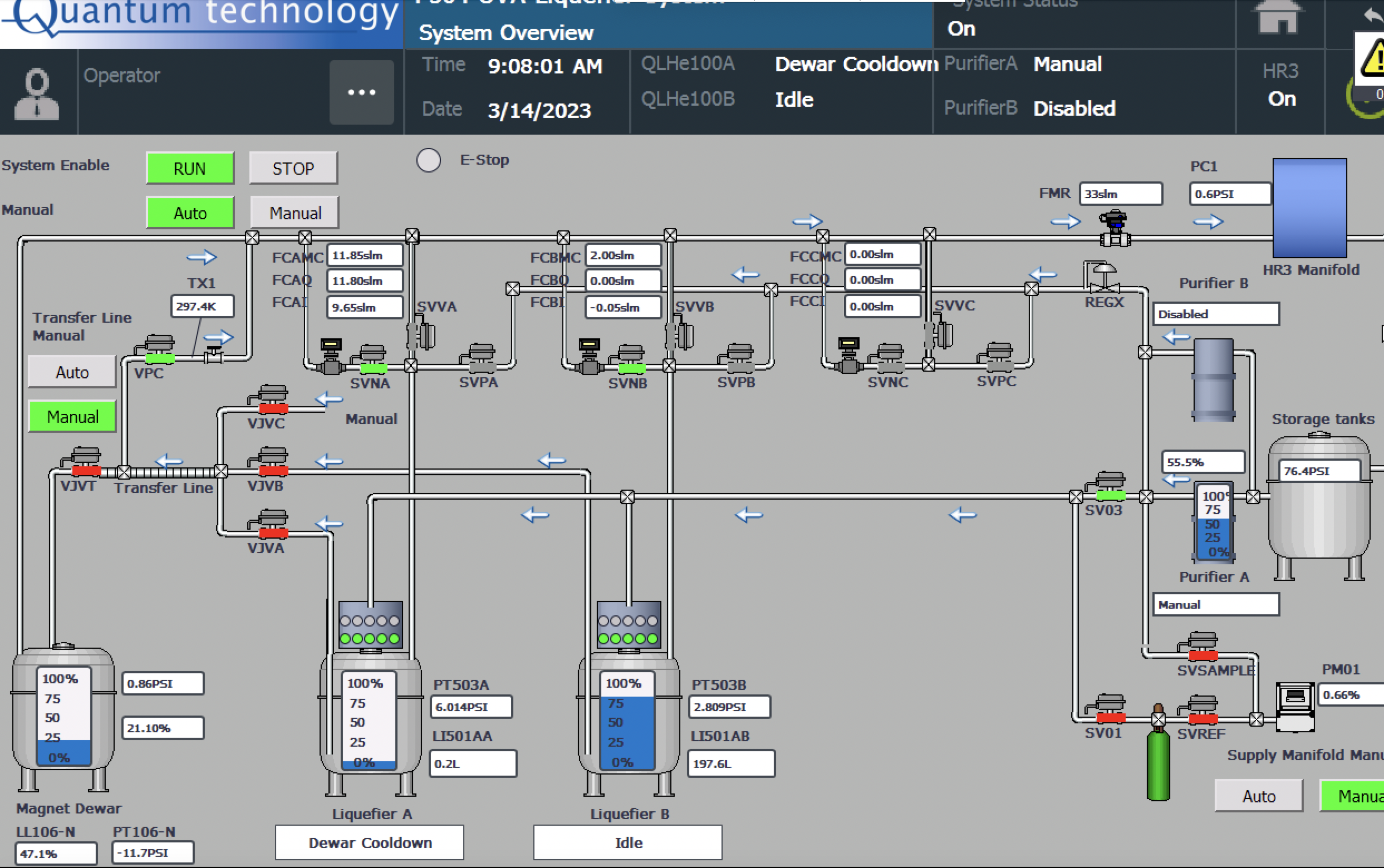

Set of slides with operational conditions (including the sub-screens): QT_Operational_Settings.pdf

For QT system maintenance, we need to keep LHe and LN2 levels in the magnet space, fridge space, magnet shield, and purifier space. There are some approved procedures from FNAL to perform these duties:

- Liquid helium fill procedure: https://seaquest-docdb.fnal.gov/cgi-bin/sso/ShowDocument?docid=9670

- In the liquid helium fill procedure; we do not need to set the "Dewar Set Pressure" to 3 psi because we swapped out the separator relief valve from 3 psi to 6 psi. So, the separator relief will not happen at 3 psi in the target cave.

- Liquid helium fill procedure: https://seaquest-docdb.fnal.gov/cgi-bin/sso/ShowDocument?docid=9670

Magnet LHe level: This LHe level should always be > 10% during the operational state. Monitor the level and arrange re-fills in a timely manner.

Note: Maximum level of the magnet is 45% due to the geometrical positioning of the level probe in the magnet.Purifier liquid nitrogen (LN2) level: This LN2 level should always be > 50%. Monitor the level and arrange re-fills in a timely manner.

Storage tank (gHe) pressure: This should be between 40 PSI and 110 PSI.

If the pressure reaches 110 PSI, then you will need to arrange to vent gHe to the atmosphere.

If the pressure is reaching 40 PSI, you will need to arrange a re-fill of gHe ahead of time.

Move Target

Before move:

- Stop Beam

- Stop Microwaves

Move Target Physically

- Verify the correct encoder value.

- Follow the instructions of Target Movement Procedure to move target.

- Start movement program, hold the button to move.

Change NMR

There are 2 NMR coils, one in the Top cup, one in the Bottom.

- Set the channel.

- Set the calibration constant.

- Select a baseline.

- Take Data and run DC Convert. Change Gain when needed.

Check Position

- Check that the beam is hitting the point on the target stick that it is suppose to

- Look at the Slow Raster images. Post them to the halog!

- Hot spots on the edges of the circle mean beam is crashing into our target cups!

- Destruction of target cups mean delays, make sure your shift worker is watching the slow raster!

Alarms and Safety

- Whenever there is any important event (major alarms, etc.) respond to the alarm first, then make screen grabs of the relevant target windows (PDP or Cryo Controls, charts, etc) and post them on the halog (with e-mail to the relevant experts, if needed)

- Correct the problem that caused the alarm before proceeding. Call if you think an expert should be consulted.

- Problems that don't cause alarms should be logged and experts consulted as needed, before proceeding.

- Whenever there is any important event (major alarms, etc.) respond to the alarm first, then make screen grabs of the relevant target windows (PDP or Cryo Controls, charts, etc) and post them on the halog (with e-mail to the relevant experts, if needed)

Log Everything

In the Paper Logbook:

- Run, Separator Valve settings

- Microwave frequency, bellows position, polarization

In the Hall A Log and Paper Logbook:

- Target movement and new encoder value

- Alarms that don't go away by themselves

- Screengrab of PDP every hour

- For the screengrab, adjust polarization graph to show how polarization has changed since last screengrab.

- Screengrab of the cryo screen at the start of your shift

- Screengrab of the slow raster plot after a target movement.